Screw conveyor(Spiral blade rotary conveying)

Screw conveyor(Spiral blade rotary conveying)

Introduction

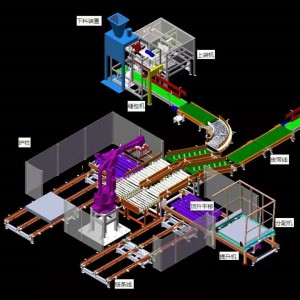

The screw feeder is one of the necessary equipments for light and heavy industries such as modern chemical industry, pharmacy, food, metallurgy, building materials, agricultural sideline, etc. It provides work efficiency, accurate transportation, reliable quality and durable, and in the feeding process The raw materials are completely free from moisture, pollution, foreign matter, and leakage. It realizes the automatic transportation of the feeding process, avoids the danger of high-altitude feeding, reduces labor intensity, and improves production efficiency. It is one of the essentials of modern enterprise civilized production.

The screw feeder can be used with various specifications of extruders and high-speed mixers, so that the plastic powder and particles are automatically fed from the storage box by the screw (the height can be determined according to the user), and the feeding is controlled by the food processor. It has the characteristics of automatic feeding, fast feeding, labor saving, safety and reliability, etc.

Feature

1. It is easy to install and can be moved, especially when feeding in a relatively high position, the work becomes safer and less labor-intensive.

2. Reasonable and advanced design, convenient operation and maintenance.

3. Adopt international advanced electrical control components to ensure safe and reliable system operation.

4. Large conveying capacity and fast feeding speed.

5. Wide range of use, can be used for granules, powders and other materials.

6. The machine has low failure rate, long service life and easy maintenance.

Pecision

1. Different positioning methods have different influence factors. For example, when the mechanical stop is positioned, the positioning accuracy is related to the stiffness of the stop and the speed when it touches the stop.

2. The positioning speed has a great influence on the positioning accuracy. This is because the energy of the moving parts that must be dissipated is different at different positioning speeds. Generally, in order to reduce the positioning error, the positioning speed should be reasonably controlled, such as improving the buffer performance and buffer efficiency of the buffer device, and controlling the drive system to make the moving parts decelerate in time.

3. The manufacturing accuracy and installation speed regulation accuracy of the precision manipulator have a direct impact on the positioning accuracy.

4. Weight of moving parts The weight of moving parts includes the weight of the manipulator itself and the weight of the object to be grasped. The change of the weight of the moving parts has a great influence on the positioning accuracy. Generally, as the weight of the moving parts increases, the positioning accuracy decreases. Therefore, the design should not only reduce the weight of the moving parts themselves, but also consider the influence of changes in the grip during work.